In the food, dairy, and beverage industries, choosing the right valve is not just about controlling flow—it is about protecting your product integrity and optimizing your production time.

One of the most common questions we get from factory engineers and procurement managers is: “Is it really worth upgrading from a standard Single Seat Valve to a Sanitary Mixproof Valve?”

The price difference is noticeable, but so is the performance difference. While single seat valves are cost-effective for simple tasks, they come with limitations that can cost you more in the long run.

In this guide, we break down the technical differences, safety factors, and ROI (Return on Investment) of both valve types to help you make the best decision for your processing line.

What is a Sanitary Single Seat Valve?

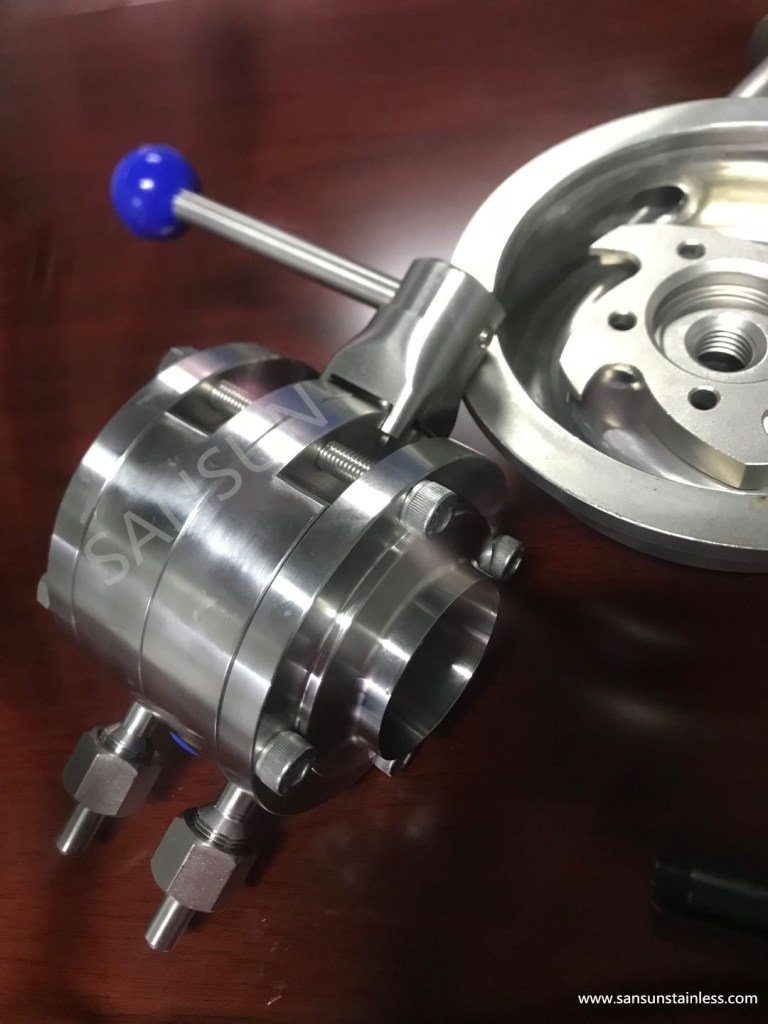

A Sanitary Single Seat Valve is the workhorse of the hygienic processing industry. It is a simple shut-off or change-over valve with one seat sealing the plug against the body.

How it works: A single seat valve uses a single seal to separate the liquid in the pipeline. When the valve is closed, the seal prevents flow.

Pros:

- Low Cost: Simple construction makes it affordable.

- Easy Maintenance: Fewer moving parts mean it is easy to service.

- Compact: Takes up less space in the piping system.

The Risk: The main limitation is that there is only one barrier between different fluids. If the seal fails due to wear or pressure spikes, the fluid in line A can mix with the fluid in line B. For this reason, you generally cannot clean one line while the other is running product—you risk cleaning chemicals mixing with your beverage or milk.

What is a Sanitary Mixproof Valve?

A Sanitary Mixproof Valve (often called a Double Seat Valve) is an advanced solution designed to separate two different products flowing through the same valve housing without any risk of cross-contamination.

How it works: Unlike the single seat valve, the mixproof valve has two independent seats and a leakage chamber in between them.

If a seal fails, the leaked liquid does not cross into the other pipe. Instead, it is directed into the atmospheric leakage chamber and drains out of the bottom of the valve. This gives the operator immediate visual indication of a leak, while the two fluids remain 100% separated.

Key Comparisons: Why Upgrade to Mixproof?

When deciding between the two, consider these three critical factors:

1. Safety & Cross-Contamination

- Single Seat: Offers minimal protection. It relies entirely on the integrity of a single seal.

- Mixproof: Offers maximum protection. The “Double Seat + Leakage Chamber” design creates a physical barrier. For high-value industries like pharmaceuticals or dairy, where a single batch contamination can cost thousands of dollars, this safety feature is non-negotiable.

2. Process Efficiency (The Game Changer)

This is where the Mixproof valve pays for itself.

- With Single Seat Valves, you typically have to shut down a large section of your plant to perform CIP (Clean-in-Place) to avoid chemical contamination.

- With Mixproof Valves, you can achieve Simultaneous Processing. You can run milk through the upper housing while running hot CIP fluid through the lower housing. This allows for 24/7 continuous production, significantly increasing your factory’s output capacity.

3. Valve Manifolds & Automation

Mixproof valves are the building blocks of modern Valve Matrices (Manifolds). Because they handle complex flow paths safely, you can automate your entire routing system, reducing manual hose connections and human error.

The Verdict: Which One Should You Choose?

Stick with a Single Seat Valve if:

- You have a limited budget.

- You are controlling simple flows (e.g., water or utilities).

- Your production schedule allows for downtime to clean the entire system safely.

- Cross-contamination risks are low or manageable.

Upgrade to a Sanitary Mixproof Valve if:

- You are producing high-value products (Dairy, Brewery, Pharma, Cosmetics).

- Efficiency is critical: You need to clean one tank while filling another.

- You want to eliminate the risk of product recall due to contamination.

- You are building an automated valve manifold.

Conclusion

While the initial investment for a sanitary mixproof valve is higher, the ability to run continuous production and the peace of mind regarding product safety often results in a higher ROI within the first year of operation.

At Sansun Stainless, we specialize in manufacturing high-quality sanitary valves that meet strict international standards. Whether you need a cost-effective single seat solution or a state-of-the-art mixproof matrix, we have the engineering expertise to support you.

Ready to upgrade your piping system? [Contact Us Today] to get a quote or discuss your technical requirements with our engineering team.